| EL34's CNC Stuff |

| Back to main CNC page |

| - |

Upgrading my CNC machine |

|

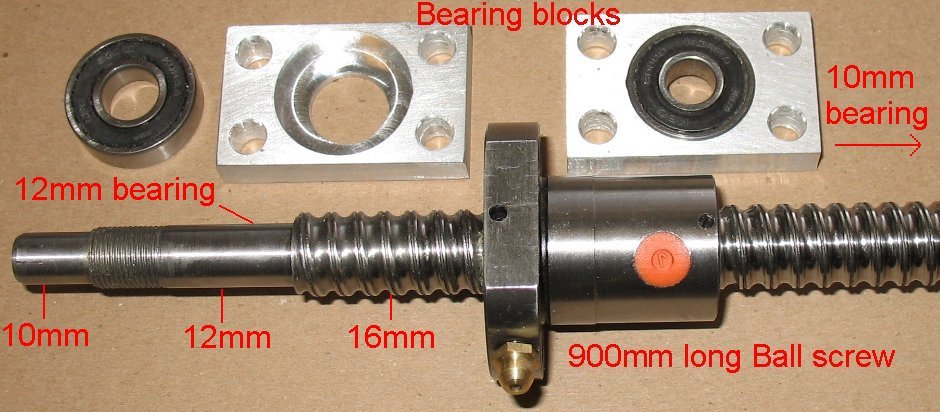

I am upgrading my CNC machine to a use Ballscrew on the X axis. My old X axis used a 1/2" diameter x 10 pitch acme screw and Delrin nuts. I purchased a 900mm long x 16mm thick metric Ball screw on Ebay and am in the process of adapting it to my X axis. I had to machine new bearing blocks for the metric bearings. I also have to machine a new motor drive coupler. My old screw was 1/4" diameter where it connected to my 1/4" drive motor. I have to machine a 1/4" to 10mm adapter |

|

| The Ballscrew and the two bearing blocks I machined |

| - |

|

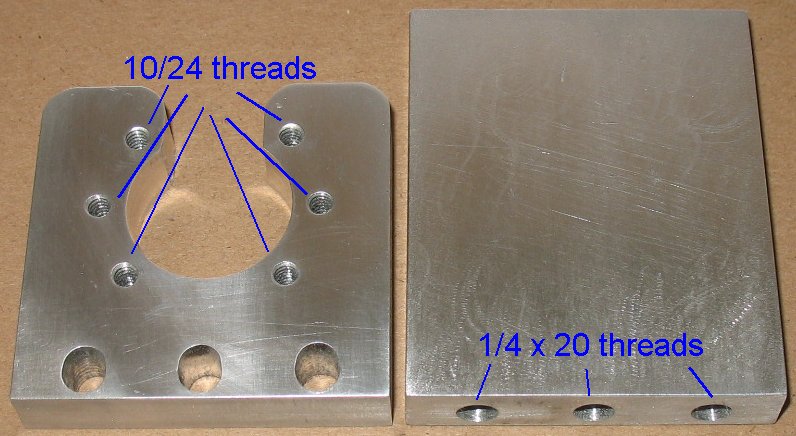

| This is the ball screw nut support I machined |

| - |

|

|

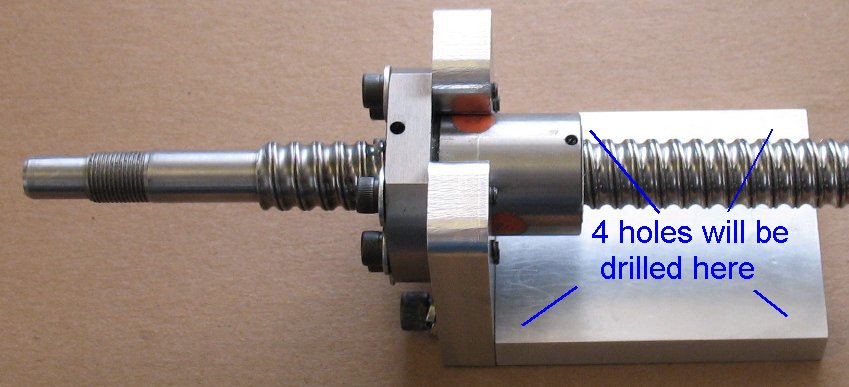

Here's the ball screw support shown mounted to the screw nut. I have to set this assembly into my machine and then drill four mounting holes. The assembly gets bolted to the lower part of my X axis/gantry |

|

| Another shot of the screw nut bolted to the support |

| - |

| Click on the image below for a larger image |

|

|

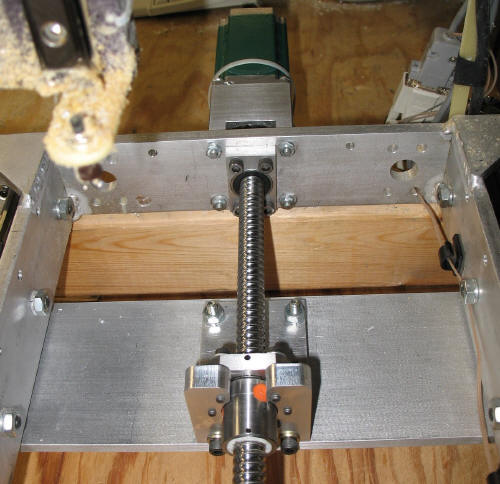

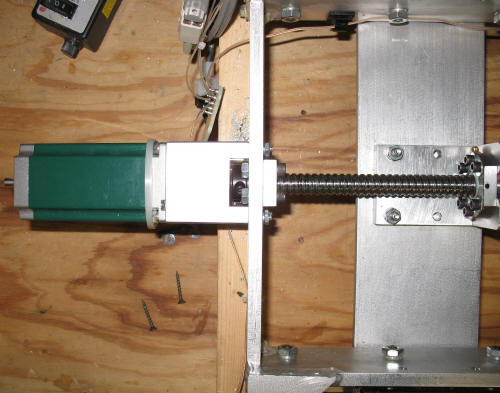

Here's a shot of the Ball screw installed. I was able to crank up the motor speeds in Mach3 after installing this screw. It is so much faster and smoother than the old acme screw and Delrin nut. |

| - |

| Click on the image below for a larger image |

|

| Another shot of the motor, motor mount, bearing block and ball screw |

Enter My Tube Amp Parts Store Here

Mobile users Enter My Tube Amp Parts Store Here

The Tube amp Library of information

Click the link above for Tube amp info, Schematics, Board building information, Projects, Mods, Transformer diagrams, Photo's, Sound clips.

There are hundreds of pages of Tube amp information on my library page.

Please visit my Tube Amplifier Forum

Here's the place you can go to ask tube amplifier questions.

You will find a large community of friendly amp builders at the link above.

Check the huge library of Schematics here

Design your own custom Turret Board or Eyelet board

DIY Layout Creator file analyzer program

DIY Layout Creator file library

Sound clips and tunes of all types

How to email me

|

MEMBER OF PROJECT HONEY POT Spam Harvester Protection Network provided by Unspam |