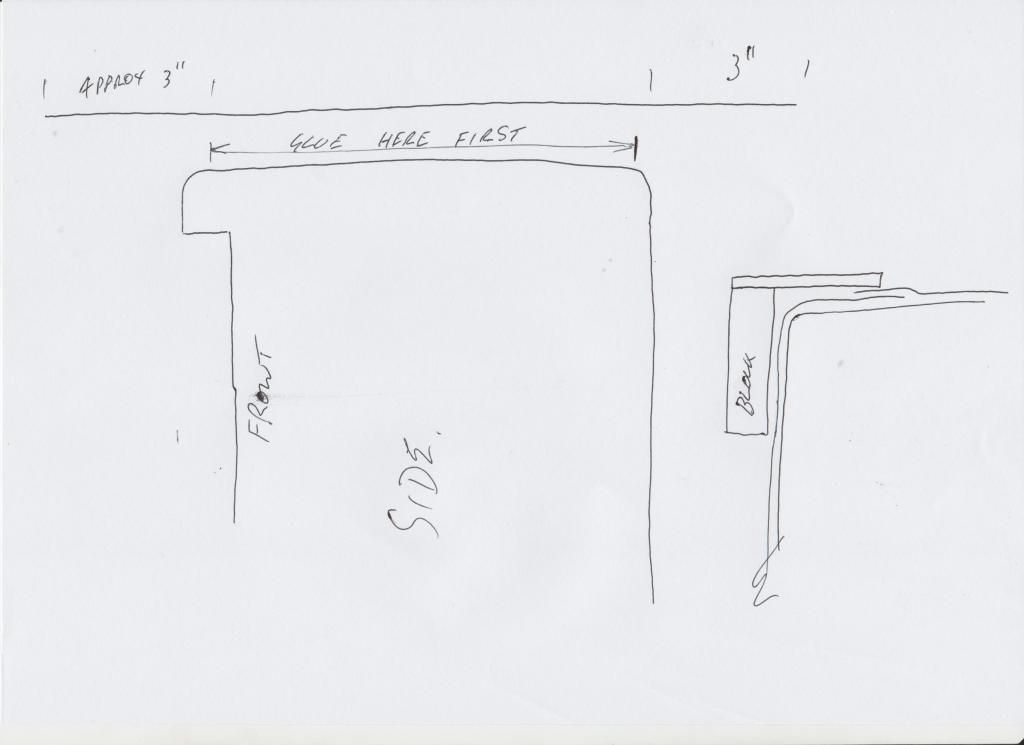

Hey alerich, I would glue to sides, top and bottom(one piece) allow a width that gives you enough that will return into the front, and about 3" return around the back. This tolex NEEDS to be parallel with the box or you will find that as you go around the sides the over hanging flaps WILL NOT BE EQUAL.

When I glue the sides(contact glue)I only paint to the edge of the round.

I usually then work on the front as this is a bit fiddly mitring corners and folding into the front of the baffle.

Paint the tolex front flap and box and work your way around and finish the corners.

With the 3"flap on the back fold into place and mark, this will give you the size for the tolex back panel, add half an inch to be sure it will cover the side flaps, cut this piece but do not glue yet.

When working on the back I do much the same thing as the front, paint the flap and the box only to as far as the flap will reach, mitre corners.

Paint back of box and tolex, place tolex so that it covers the side flaps by the half inch and smooth into place.

Make a guide that will guide a knife at a set distance from the edge of the box and cut through both layers of tolex.The glue under the first layer of tolex will still be "green" (not cured)this will allow you to peal the excess tolex of the first layer( touch up any of the glue that comes off with the tolex) work the tolex into the cut joint closing any gaps.If need be some duct tape can be stretched across the joint this will pull the tolex together till the contact properly sets.